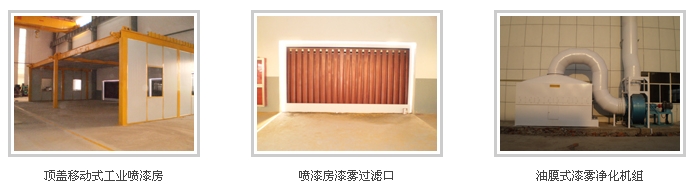

Paint mist purification equipment

Introduction to YMJ series oil film paint mist purifier

1. Design indicators: After paint mist purification treatment, the following performance indicators should be achieved

Paint mist purification rate: ≥ 95%

Equipment resistance: ≤ 40mmH20

Operating noise: ≤ 85dB (A)

Harmful exhaust gas emission concentration

Benzene ≤ 40mg/m3

Toluene and xylene ≤ 100mg/m3

2. At present, the commonly used paint mist purification devices in China are basically divided into water curtain type, oil film type, and activated carbon adsorption.

Comparison of oil film, water curtain, and activated carbon adsorption purification devices:

Water curtain type: Its paint mist removal rate is basically the same as that of oil curtain type, but its adsorption capacity for organic waste gas is very low, which cannot meet the emission standards for waste gas.

Activated carbon adsorption: Although the adsorption of organic waste gas can meet emission requirements, the purification rate of paint mist is not high, and activated carbon is easily saturated and needs to be replaced frequently, resulting in high operating costs.

Oil film type: Due to the use of a mixture of mineral oil and diesel oil as an adsorbent and adhesive for paint mist, it can effectively remove harmful gases in the paint mist while removing it. During operation, there is less oil loss, and the effective service life of mineral oil is about 2 years, with a long service life and no secondary pollution.

In summary, the best way to purify paint mist and organic waste gas is through oil film purification. However, in order to thoroughly remove organic waste gas and meet the emission standards of benzene and xylene, an additional stage of activated carbon adsorption can be added after the oil film paint mist purification device to achieve good results in paint mist purification and organic waste gas adsorption without increasing the equipment volume as much as possible.

3. Working principle and structural characteristics of YMJ series oil film paint mist purification

The paint mist generated by the painting of workpieces in the paint booth enters through the front (or ground) suction port of the paint mist purification device and mixes with the machine diesel mixed oil on the second row oil film plate at the inlet of the purification machine. The paint mist particles and harmful gases such as benzene and toluene are basically dissolved in it. After filtering through the oil blocking plate, the vast majority of the oil mist in the oily gas is filtered out. In the final stage, it is filtered through activated carbon filter cotton to adsorb all residual oil mist and harmful gases. The purified gas is discharged into the atmosphere through the fan and the seventh exhaust pipe.

Structural features:

A. Adopting a dual oil film design improves the mixing effect of paint mist and mixed oil.

B. The level of the oil tank can be adjusted to ensure the uniformity of the oil film on both sides.

C. Increase activated carbon adsorption for more thorough purification.

D. Adopting a top frame replacement structure makes it more convenient to replace the filter frame.